AI Powered Pit Analysis is Making Mine Site Safety and Compliance Fast, Easy, and Affordable.

Mine Safety and Compliance is Getting A Lot of Bad Press

In 2019 (going back to a “business as usual” pre pandemic year), MSHA conducted 37,471 inspections at nearly 13,000 mines employing 330,000 miners, which resulted in 99,663 citations and orders.

These tragedies have resulted in significant losses and liability for the mining industry, the workers, and the communities in which they exist. Tragedies that could have been avoided or at least mitigated with proper monitoring.

Mines all over the globe are facing increasing scrutiny and regulation as public attention is focusing on these avoidable accidents and the property loss, environmental destruction, injuries, and even death that occur because of failure to adequately monitor, update, and plan for mining operations.

One of the best ways to proactively address compliance and safety issues is to conduct regular pit analyses. Traditionally, pit analyses have been long, laborious, disruptive undertakings that made their benefits unattainable for a large number of companies. But, by adding drones and AI to the pit analysis workflow it has become easy, fast, and affordable to make compliance and safety a priority.

When Should You Consider Pit Analysis?

Mines are planned for safety and compliance. However, big problems can occur as sites evolve over time. Monitoring actual site conditions and accounting for them in daily operations planning is critical for safety and compliance. Mines need to periodically conduct a pit analysis, to quantify the real-world version of their site. Once the true dimensions of the mine as it exists are understood, mines can adjust their operations to ensure safety and compliance.

Some questions to ask yourself:

- Do your pit slopes, embankments, and benches match the designed plan?

- Are their angles and heights within safety parameters?

- Are your catch benches wide enough?

- Are your berms axle height?

- Are your haul roads wide enough for all of your necessary equipment to navigate safely?

- Do you know the grade of your haul roads?

- Is water eroding, pooling, or creating areas of concern in your site?

- Have you updated your mine/operations plan within the past 6 months, quarter, month?

- Have you incorporated rock mass data into your blasting, haul road, ramp, and slope design?

If your answer to any of these is “no” or “I don’t know,” then you need to do a pit analysis as soon as possible.

Making Pit Analyses Easy, Fast, and Affordable with Artificial Intelligence

Doing pit analyses using artificial intelligence is fast, easy, and affordable. Whether you use drones, satellites, lasers, or sensors, the software collects the data and analyses it for you. AI combs through mountains of information, reaches conclusions, and creates reports, maps, and charts in minutes. Using AI allows you to have the most up to date information on your site possible and allows you to optimize your operations for safety and compliance.

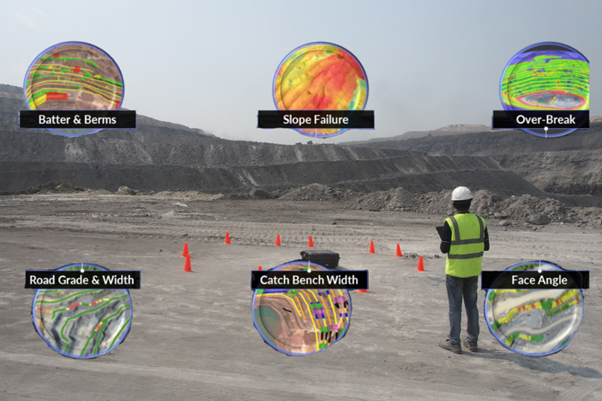

There are many ways using an AI powered Site Intelligence tool can increase safety and compliance. Here are just a few:

- Slope measurement and monitoring– Measure your slope angles and monitor for deformations and potential failures whether they are pit slopes, tailings embankments, stockpiles, whatever.

- Bench mapping– Detect toe and crest, measure your bench height, bench face angle, and inter-ramp angles.

- Berm and Haul Road tracking– Measure and map the width and grade of your roads and your berm heights.

- Water flow tracking and monitoring– for erosion, structural weakening, flooding, and more.

- Slope Failure Prediction and Shot planning– use Rock Mass Detection to identify and locate bedding planes, joints, and discontinuities and measure their dip and dip direction. Add to it Measure While Drilling data to avoid potential slope failures and assist in shot planning to optimize shots reducing the risk of fly-rock, and excess noise and vibration.

- Mine progression tracking– Track the evolution of your mine over time, ensure that changes are measured and deviations are tracked to plan better for the future operations.

Automated Notifications for Safety Risks and Non-Compliances

Adding AI powered pit analysis means you can be warned about a violation automatically rather than having to proactively investigate and monitor. No more having to go out and visually inspect a feature to make sure its compliant. For example:

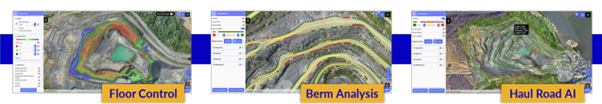

Haul Road Monitoring

The AI automatically detects, measures, quantifies, and color codes your haul roads based on compliance with your design parameters to show you areas of concerns. All you have to do is toggle on the haul road feature and the map is right there.

Slope Monitoring

The AI automatically detects rock mass characteristics and can warn you if the characteristics of the slope warrant special treatment- like a lower slope angle or additional monitoring. Additionally, if there are any changes to that slope- cracks, deformations or expansions due to weather, seismic activity or otherwise, it can warn you immediately of increased risk.

Protect Your Workers and Ensure Compliance

Pit Analyses have traditionally been time consuming and expensive- but not anymore. Modern technology has significantly sped up and automated the pit analysis process making it affordable and easy to significantly reduce safety and compliance violation risks.

Drone and AI powered pit analysis can be completed without big price tags. Without any significant logistical undertakings, and without any operational interference.

All you need to do is perform a drone flight and then upload the data to the software. The software automates the analysis so that you have the information you need in minutes with minimal resources, and no operations disruption.

Using AI powered Pit Analysis can help insure you are creating the safest, most compliant site for your workers.

Our Partners