Using Drones & AI for Automated Geometric Reconciliation & Pit Analysis

Summary

The geometric reconciliation of mining development is the quantification of the differences between the real state of its slopes, banks, and berms, among others, and its original design. This is critical to meeting safety, production, and operating cost targets. The major causes for not achieving the mine design include improper blasting or excavation practices and not having regular up-to-date as-built data.

Traditionally, Pit Analyses and Geometric Reconciliations have only been performed very occasionally by large mines who could afford the large costs and operations interruptions. Now with drones and AI Pit Analyses, including geometric reconciliations, can be done quickly, affordably, safely, and with no interruptions to operations.

Discusses how drone data and AI can fully automate the geometric reconciliation and pit analysis using 3D survey data. This allows the geometric reconciliation and topographic survey of different production scenarios automatically, quickly, and with reliable results so that you can improve safety, productivity and compliance on your site.

Learn how to use the power of AI to analyse Design Conformance KPIs like:

- Batter & Berm Compliance

- Over-break & Underbreak Compliance

- Crest Loss & Toe Flare

- Effective Catch Capacity

- Inter-ramp Compliance

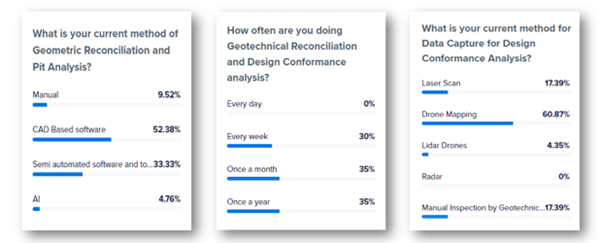

Polls

With over 250 registrants we had excellent audience participation. Here are the poll questions asked and their responses:

New technologies are rapidly changing the drilling, blasting, mining, and aggregates industries, empowering them in ways never before possible. Make sure you are taking advantage of the best tools available.

Our Partners